-

Car Reviews

- All reviews

- Midsize SUVs

- Small cars

- Utes

- Small SUVs

- Large SUVs

- Large cars

- Sports SUVs

- Sports cars

- Vans

Latest reviews

- Car News

-

Car Comparisons

Latest comparisons

- Chasing Deals

The new approach – called ‘X-in-1’ – hopes to make Nissan’s E-Power electrified systems as affordable as ICE cars

Nissan Motor Corporation has today announced its new approach to building more cost-effective electrified powertrains, with a goal to bring price parity between its E-Power hybrid powertrains and traditional combustion engines by around 2026.

The new strategy – called ‘X-in-1’ – aims to cut development and manufacturing costs by 30 percent by sharing and modularization components between its hybrid and fully electric drivetrains.

As part of its Ambition 2030 target, Nissan aims to have 27 electrified vehicles and 19 fully-electric vehicles in production by the end of the decade.

Nissan currently offers the fully-electric Leaf hatchback in Australia, one of the first mass-produced electric vehicles to hit the market and offers the Ariya midsize SUV overseas.

The brand’s e-Power hybrid technology was first introduced in 2016 and is available in the X-Trail in Australia, with the Qashqai set to gain the option locally at some point in 2023.

The ‘X-in-1’ system is essentially the sharing of electrical elements across both full EV and hybrid systems.

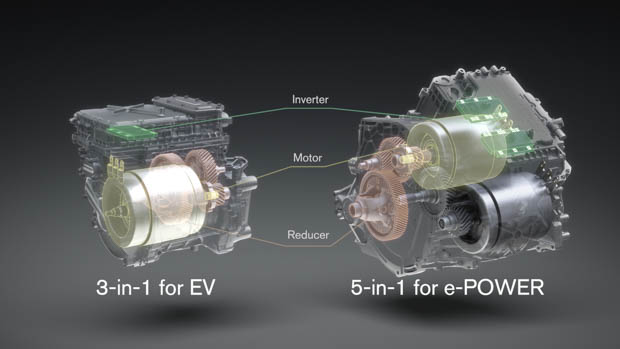

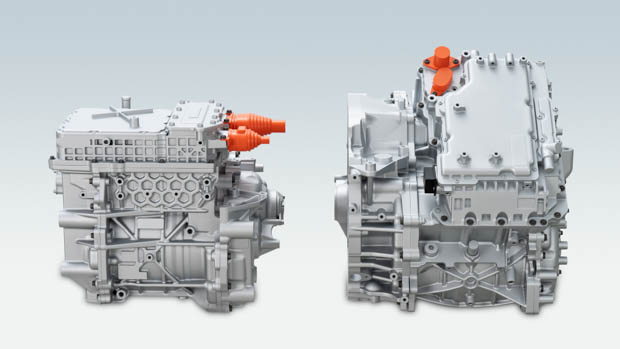

Nissan’s internal sharing of EV powertrain technologies between E-Power hybrid and full EV vehicles has allowed the company to develop a three-in-one prototype that modularises the motor, inverter and reducer for full-EV models.

A larger five-in-one system prototype, which is planned for use in E-Power hybrid vehicles, adds a generator and increaser to the mix.

Currently, the Nissan X-Trail Ti E-Power is priced from $54,190 before on-road costs – almost $5000 more expensive than its ICE X-Trail counterpart. However, Nissan hopes to shorten this price gap with the implementation of its ‘X-in-1’ electric development approach.

Nissan says there are several benefits to their new development approach for its electrified cars.

The key benefit is that by sharing core components across hybrid and full-electric powertrains, it will ultimately increase efficiency and cut production costs. This could potentially lead to cheaper electrified vehicles released in future years.

Secondly, by reducing the overall size and weight of the electric power units, Nissan states that there will be improved driving performance, with minimal noise and vibration aiding passenger ride comfort.

Finally, Nissan aims to reduce the use of rare earth elements in the drive motor to just one percent or less of the unit’s total weight. By doing so, Nissan can reduce higher costs of sourcing such elements, as well as reducing pollution and risk to human safety.

Latest news

About Chasing cars

Chasing Cars reviews are 100% independent.

Because we are powered by Budget Direct Insurance, we don’t receive advertising or sales revenue from car manufacturers.

We’re truly independent – giving you Australia’s best car reviews.