-

Car Reviews

- Car News

-

Car Comparisons

Latest comparisons

- Chasing Deals

Tesla could build a cheaper electric car than the current Model 3 at a brand-new Indian gigafactory

Tesla could be in the planning phase of building a cost-effective new electric car in India and if the Californian startup gives the project the green light, Australia could get its most affordable electric car to date.

New reports from Reuters state that Tesla representatives are due to meet India’s commerce minister to discuss the production of a USD$24,000 (AUD$35,300) electric vehicle for both local and export markets in the near future.

In May this year, Reuters also reported that Tesla executives visited India and held meetings regarding establishing a manufacturing base for both cars and batteries packs in the country.

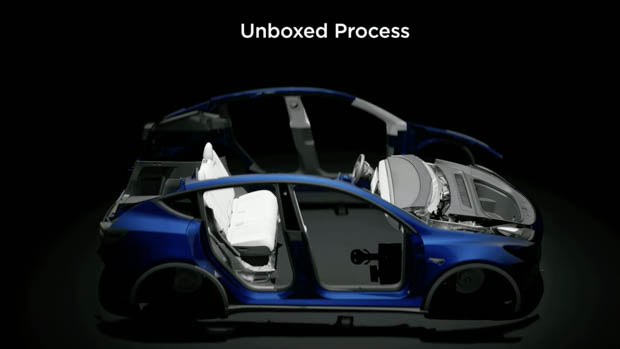

Tesla has previously stated that its next model and platform will cut production costs by up to 50 percent by using new technologies and smarter production methods, and an Indian gigafactory would fit that forecast.

The electric car maker is also investing in lithium production and will build a new in-house production facility in Texas. It will soon begin to produce its own battery packs, eventually replacing currently used CATL, LG and Panasonic units.

It’s estimated that the next Tesla model which is yet to be officially named or announced could go on sale as soon as 2024 or 2025.

Tesla currently has gigafactories operating in Texas, Mexico and in Shanghai, China.

When the Shanghai gigafactory first began production, CNN reported that the facility was 65 percent cheaper to build than the Model 3 factory in the United States.

At a size of approximately 120 football fields, the Shanghai production plant has been enhanced to produce up to 1.75 million cars annually, which works out to roughly 33,000 cars produced each week.

But why would Tesla look to India to build more cars?

By building a production facility in India, Tesla could produce a budget-oriented car for a very low price thanks to lower labour costs, raw material cost and higher total output – similar benefits achieved through Chinese production.

However, a report by MES stated that in 2015 that the average labour costs for China were $3.52 per hour, whereas in India, labour costs are approximately $0.92 per hour. For comparison, the average hourly labour cost in the USA is an estimated USD$28.

But India is also a huge market for car manufacturing. It’s currently the third biggest car producer in the world, behind China and the United States.

The next Tesla which could be called the Model 2 or Model Q is likely to be a small hatchback-sized vehicle with a single electric motor fitted to the front or rear axle.

Looking at the current Model 3 for reference, the smaller and cheaper Tesla could use a battery around 45kWh to 50kWh in capacity, not only reducing weight but also battery cost. For reference, the current Model 3 uses a 57.5kWh battery pack in standard guise.

Expect a central touchscreen in typical Tesla fashion, along with turbine-style wheels. In terms of exterior styling, imagine a smaller and more squashed Tesla Model 3 with similar design elements to the rest of the range.

Latest news

About Chasing cars

Chasing Cars reviews are 100% independent.

Because we are powered by Budget Direct Insurance, we don’t receive advertising or sales revenue from car manufacturers.

We’re truly independent – giving you Australia’s best car reviews.